Specialty Products

Specialty Products

Custom Fabricated Pipe supports & U-Bolts for piping

Hot Induction Bends 4D,5D with/without inlays in Inconel, Sterlite 6 etc

4130 API 6A Flanges, block type fittings, hammer unions and flange adaptors

Cupro – nickel Pipes and Fittings

Special Fasteners – made of exotic materials – customized threads

Parts made of special polymers (Teflon, nylon, peek …), Rubber …gaskets (special applications)

Custom Machined AB2 bushes thread adaptors, Plugs, etc to meet different thread standards

Standard and Non standard Blind Flanges in MS, SS to meet customer requirements

Polymer Sliding Bearing Pipe Supports for chilled water pipes etc..

Pipe Clamps Custom Fabricated – for small – medium – large size pipes

Various custom fabricated Brackets, Lighting Brackets

Customized SS tags,Shims, Teflon-SS pipe supports

Copper Bus Links, Copper Flexibles, Earthing Materials etc… Tin / Silver Plated

HVAC and medical copper tubes and fittings

Brass fittings & accessories for fire hydrant lines

Pumps / Electrical / Mechanical spares

Project Commissioning Materials

- Aluminium Bronze Valves

- Specialty Pipes

- Valves Industrial

- HIPPS Systems

- Flanges Industrial

Nickel Aluminium Bronze Valves

We supply a diverse range of specialty valves by type, material, and size, providing gate, globe, check (swing and wafer style), ball, Y-type pattern strainers and butterfly valves, in sizes from 1/4″ to 48″ with a focus on high alloys associated with handling corrosive media mainly Nickel Aluminium Bronze

- Gate

- Globe

- Ball

- Swing Check

- Wafer

- Butterfly

Gate Valve

- Size Range: 1/2″ – 48″ DN15 – DN1200

- Pressure Rating: ANSI 150 up to 900

- Design Standards: API 600 / API 603 / BS 1414 / BS EN 12288 / MSS SP80 / BS 5154 / BS EN ISO 10434

- Design Configurations: Bolted / Union Bonnet Rising / Non-Rising Stem Inside / Outside Screw Stem Solid / Flexible Wedge Firesafe

Globe Valve

- Size Range: 1/2″ – 32″ DN15 – DN800

- Pressure Rating: ANSI 150 up to 900

- Design Standards: API 623 / BS 1873 / BS 5154 / MSS SP80

- Design Configurations: Bolted / Union Bonnet Rising / Non-Rising Stem Inside / Outside Screw Stem Firesafe

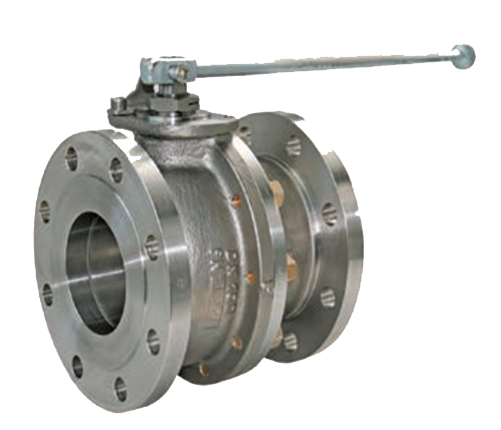

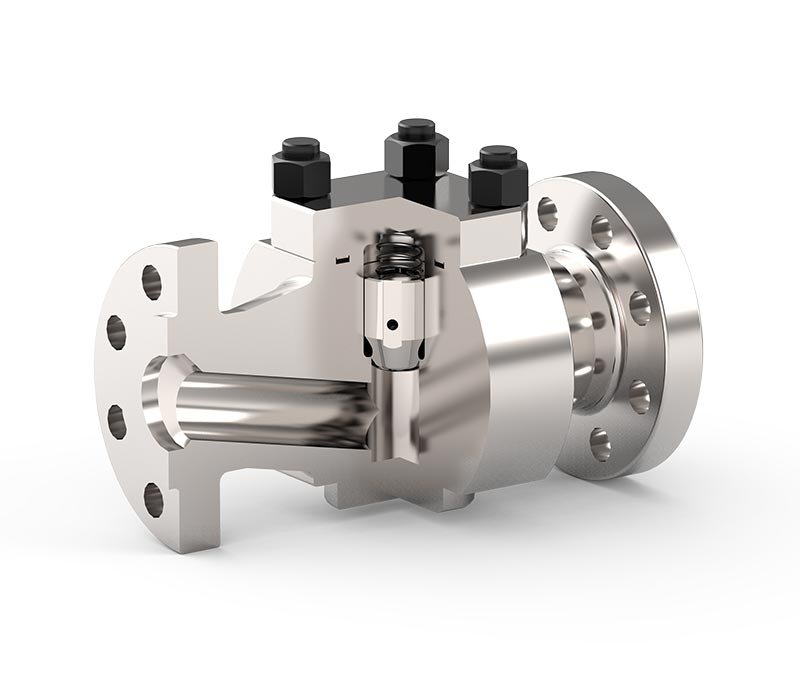

Ball Valve

- Size Range: 1/4″ – 24″ DN8 – DN600

- Pressure Rating: ANSI 150 up to 1500

- Design Standards: BS 5351 / BS EN ISO 172 92 / MSS SP72 / API 6D

- Design Configurations:1 piece, 2 piece, 3 piece Constructions Blow out Proof Stem Floating and Trunnion Mounted Ball Firesafe / Anti-static Device 3

Swing Check Valve

- Size Range: 1/2″ – 32″ DN15 – DN800

- Pressure Rating: ANSI 150 up to 900

- Design Standards: BS 1868 / BS 5154 / MSS SP80 / API 594

- Design Configurations: Bolted / Union / Screwed Bonnet Swing / Lift / Wafer Firesafe

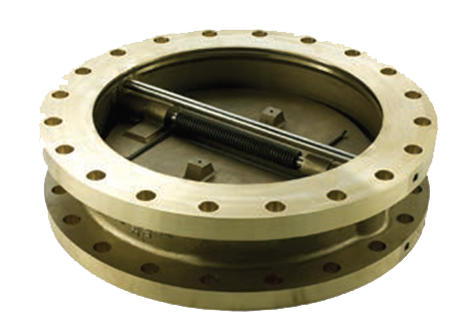

Wafer Valve

- Size Range: 2″ – 42″ DN50 – DN1050

- Pressure Rating:ANSI 150 up to 1500

- Design Standards:API 594

- Design Configurations: Dual Plate / Retainerless Wafer / Wafer Lugged / Double Flanged Metal to Metal Seats / Soft Seats Plate support bearing on larger sizes Firesafe.

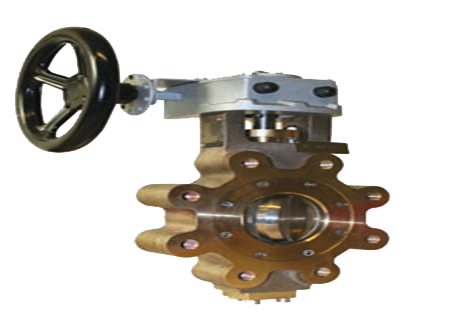

Butterfly Valve

- Size Range: 2″ – 48″ DN50 – DN1200

- Pressure Rating: ANSI 150 & 300

- Design Standards:API 609

- Design Configurations: Bidirectional Double / Triple Offset Wafer / Wafer Lugged / Double Flanged Firesafe / Anti-static Device

Specialty Pipes

We supply a range of specialty piping material at short lead times to suit our customer’s complex technical requirements. The diverse range of products include Hollow Bars, Fittings, Flanges, Nozzles and other Special Parts in varied materials of Carbon steel, Low alloy steel, Stainless steel, Duplex and super duplex, PH steel and High nickel alloy. Materials suitable to an array of projects and markets Petrochemical plant projects, Subsea Oil and Gas, Ship Building, Nuclear Power Plants and Large Civil Works to name a few.

Valves Industrial

We supply High Quality and tailor made ball, gate and check valves targeting oil & gas exploration and production sectors, including subsea and transmission, and other special service industrial application.

- Ball Valves

- Gate Valves

- Check Valves

- Special Design

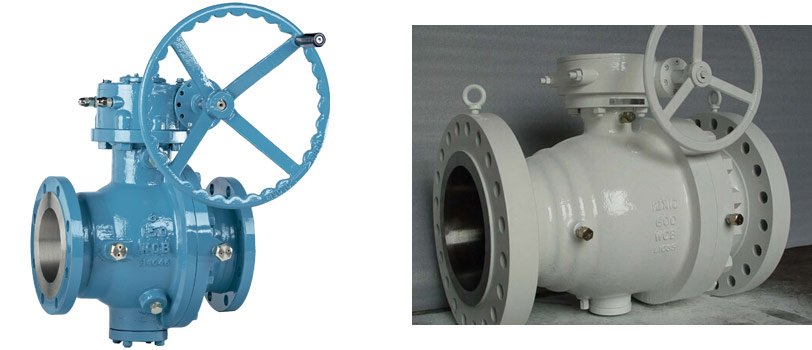

Ball Valves

Side Entry, Top Entry, Sub Sea

Floating

Size Range: 1/2″ to 6″

Applicable Standard: API 6D, API 6A, ASME IIX div. 1 & 2, ASME B16.34

Material: Low Alloy, CS, LTCS, SS, Super Duplex SS, 6MO, Inconel, Incoloy, Hastelloy, Monel, Titanium. Customised requirements such as Internal Corrosion Resistant Alloy Welded Overlays on Low Alloys, CS and LTCS can also be supported

Trunnion

Size Range: 1/2″ to 42″

Applicable Standard: API 6D, API 6A, ASME IIX div. 1 & 2, ASME B16.34

Material: CS, LTCS, SS, Duplex SS, Super Duplex SS, 6Mo, Inconel, Incoloy, Hastelloy, Monel, Titanium

Top Entry

Size Range: 1/2″ to 56″

Applicable Standard: API 6D – API 6A – API 6DSS – ASME B16.34 – ASME VIII div. 2

Material: Low Alloy, CS, LTCS, SS, Super Duplex SS, 6MO, Inconel, Incoloy, Hastelloy, Monel, Titanium. Customised requirements such as Internal Corrosion Resistant Alloy Welded Overlays on Low Alloys, CS and LTCS can also be supported

Through Conduit Gate Valves

Slab, Double Expanding, Single Expanding

- Size Range: 1″ to 56″

- Applicable Standard: API 6D – API 6A – API 6DSS – ASME B16.34 – ASME VIII div.2

- Material: Low Alloy, CS, LTCS, SS, Super Duplex SS, 6MO, Inconel, Incoloy, Hastelloy, Monel, Titanium. Customised requirements such as Internal Corrosion Resistant Alloy Welded Overlays on Low Alloys, CS and LTCS can also be supported.

Check Valves

Dual Plate Check Valves

- Size Range: 2″ to 30″

- Applicable Standard: API 6D – API 6A – API 6DSS – ASME B16.34 – ASME VIII div.2

- Material: Low Alloy, CS, LTCS, SS, Super Duplex SS, 6MO, Inconel, Incoloy, Hastelloy, Monel, Titanium. Customised requirements such as Internal Corrosion Resistant Alloy Welded Overlays on Low Alloys, CS and LTCS can also be supported.

Custom Made Special Design

Short Pattern, Annulus, Mechanical

Short Pattern

Long life valve

Complete FEA supplied

Size: 34″ 900#

Annulus

Full Duplex Valves

Size: 2.1/16″ 5000 psi

Standard: API 6A PSL 3G

Mechanical

Light double ball valve

Material: Titanium

Connecting solution

Application on pressurised lines

HIPPS Systems

HIPPS (High Integrity Pressure Protection System) is an independent SIS (Safety Instrumented System) designed to protect downstream lines and plant portion from overpressure events.

It is normally used to replace partially or completely the flare and relief system as a result of an increased environmental awareness.

HIPPS is the ultimate and independent safety layer of a plant on prevention of dramatic event.

The HIPPS system consists of at least three elements: initiators, logic solver and final elements. The main standards applicable to HIPPS are IEC 61508 and IEC 61511.

Flanges Industrial

We supply a range of High Quality Specialty Industrial Flanges and Forgings at short lead times to satisfy even the most complex applications and customer needs. The range of products include Nipo Flanges, Anchor Flanges, Compact Flanges, API Flanges, Misalignment Flanges, Weld Overlayed / Cladded Flanges, Adaptors, Closures, Connectors, Nozzles, Welding Neck to name a few produced and verified for high reliability usage fit for both liquid and gas fluid transportation and transformation as well as for off shore and sub sea applications.