Services

Comprehensive Solutions for Industry Excellence

Empowering Industries with Precision, Innovation, and Expertise

At Solvo Mech, we pride ourselves on delivering a diverse range of services tailored to meet the unique demands of global industries. From precision bolt torquing and customized casting to advanced fabrication and project management, our solutions are designed to enhance performance, reliability, and efficiency. Leveraging cutting-edge technology and a team of seasoned professionals, we ensure exceptional quality, timely delivery, and unmatched customer support.

Our service portfolio reflects our commitment to excellence, innovation, and sustainability, helping clients achieve operational success across sectors like oil and gas, petrochemical, power, water transportation, and more.

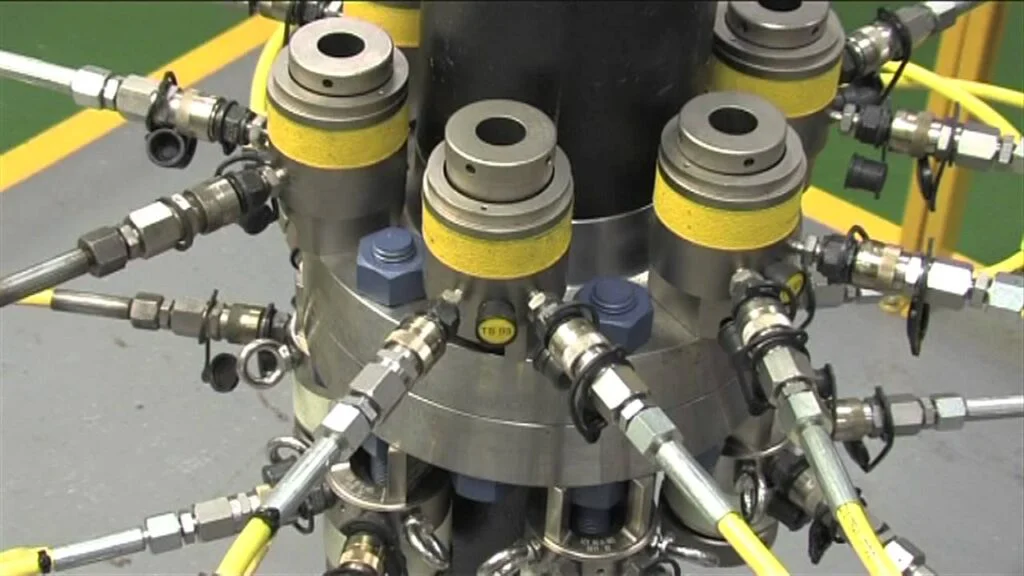

Bolt Torquing

Bolt torquing is a critical service for industries that rely on the precise assembly of equipment and systems. We offer professional bolt torquing services to ensure optimal tightening of bolts to their specified torque values.

Our services include:

Precision Tools and Equipment

Utilizing advanced torque tools and hydraulic tensioners to deliver accurate and consistent results.

Safety Assurance

Ensuring all bolted connections meet safety and operational standards, minimizing the risk of leaks or failures.

Versatility

Capable of handling a wide range of applications, from pipeline flanges to heavy machinery assembly.

On-Site Services

Providing bolt torquing at your facility or project site, ensuring minimal disruption to operations.

Our expertise in bolt torquing helps maintain the structural integrity of critical components, reducing the likelihood of unplanned downtime and enhancing system reliability.

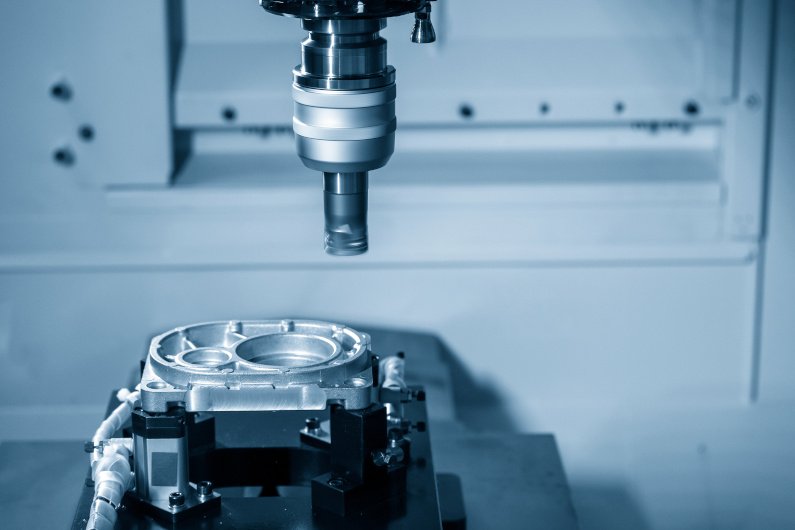

Customized Casting & Machining

We offer comprehensive customized casting and machining services to meet the unique needs of our clients. This service is tailored to industries requiring precision-crafted components that adhere to specific dimensions, materials, and tolerances.

Key features include:

Casting Capabilities

Producing components in a wide variety of metals, including stainless steel, carbon steel, and alloys, using methods like sand casting, investment casting, and die casting.

Advanced Machining

Precision CNC machining for detailed work, including drilling, milling, turning, and grinding to achieve exact specifications.

Prototyping & Production

Supporting both small-batch prototyping and large-scale production with consistent quality.

Customization

Designing components to meet specific application requirements, including high-pressure, high-temperature, and corrosive environments.

Our customized casting and machining services ensure high-quality components that enhance performance and longevity across various industrial applications.

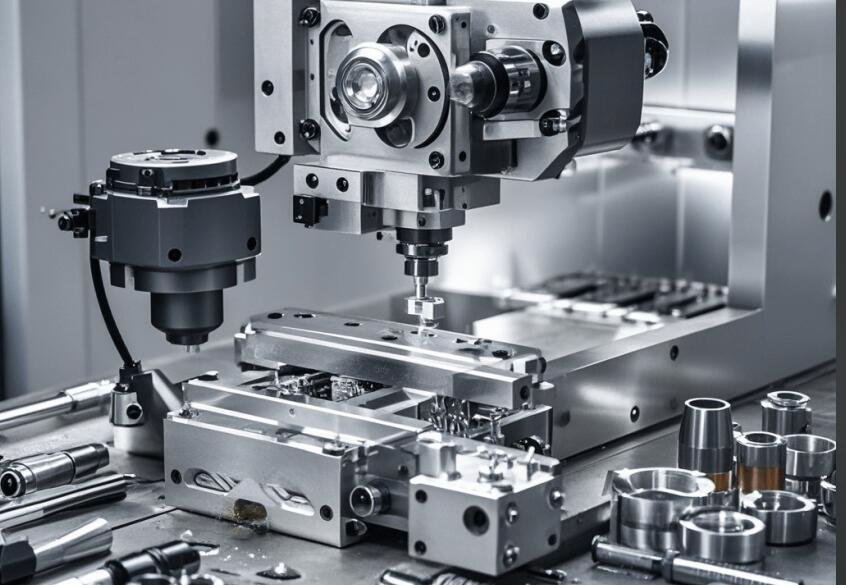

Fabrication

Fabrication is at the core of creating robust and reliable industrial components. Our fabrication services are designed to meet the most demanding requirements with precision and quality.

Highlights include:

Metal Fabrication Expertise

Fabricating custom structures and components using cutting-edge techniques like welding, bending, cutting, and assembling.

Wide Material Range

Working with a variety of materials, including steel, aluminum, and specialized alloys, to suit different industrial needs.

Custom Designs

Creating tailor-made solutions for pipelines, pressure vessels, frames, and other industrial equipment.

Quality Assurance

Adhering to international standards and conducting rigorous inspections to ensure durability and performance.

Our fabrication services combine technical expertise with innovative approaches to deliver solutions that meet the highest industry standards.